Enabled by predictive AI and self-learning systems, factories are transforming from static assets into dynamic, intelligent networks. Your plant isn’t just responding, it’s foreseeing, evolving, and at times, operating beyond human speed and insight.

As factories begin to “think” quicker and more precisely than their human overseers, a pressing question arises: What if your plant anticipates what lies ahead before you?

Traditionally, industrial plants functioned reactively, equipment malfunctioned and quality problems emerged before technicians responded, leading to expensive downtime. Predictive AI alters this by examining sensor data and real-time measurements to identify early indicators like vibrations or temperature variations, allowing the facility to “anticipate” issues, predict faults, and autonomously initiate preventive measures, transitioning from human led interventions to AI driven foresight that averts disruptions.

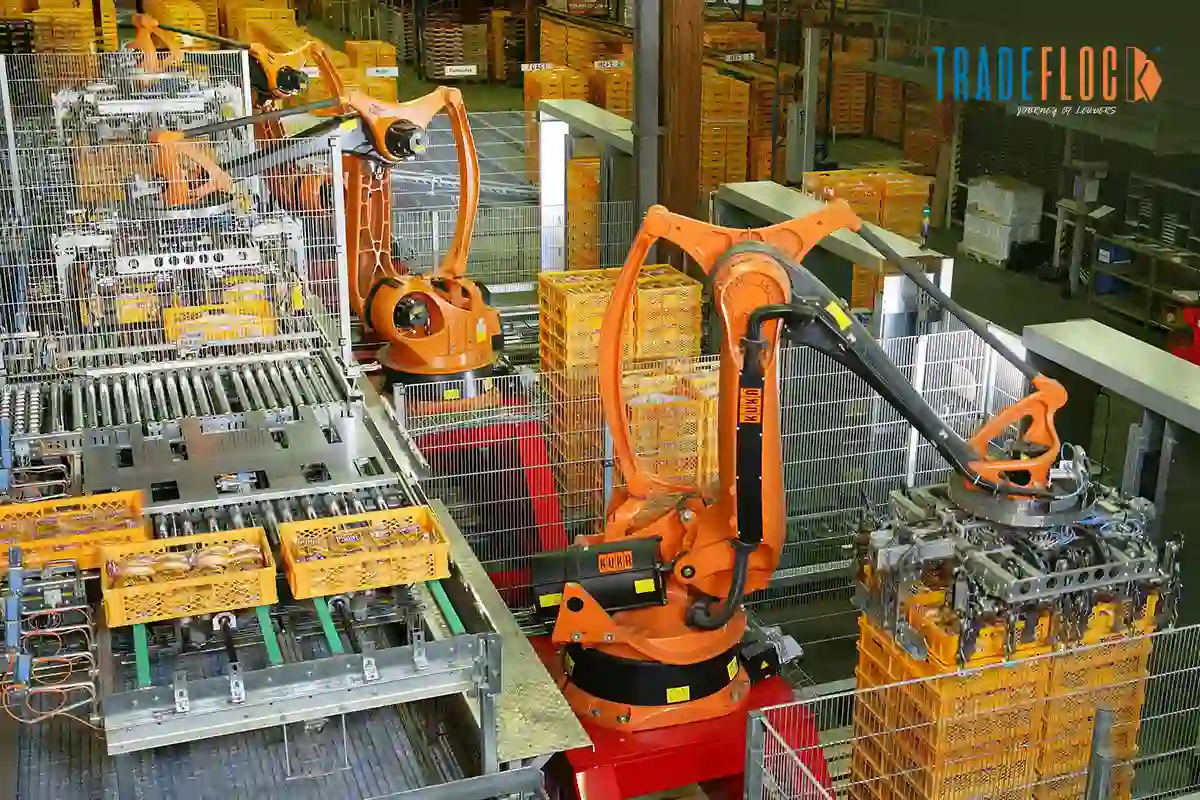

Building on predictive AI, self-optimising factories independently modify operations instantly, adjusting speed, temperature, and processes. For example, production lines fine tune for raw material variations, and logistics redirect to prevent obstructions. Utilizing machine learning, edge computing, and IoT, these systems constantly evolve, minimizing downtime, improving quality, reducing waste, and increasing flexibility.

Some real world examples are leading the way.Sectors such as automotive, pharmaceuticals, and semiconductors are already reaping the benefits of predictive AI and self-optimising technologies. Automakers like BMW and Tesla employ predictive maintenance to minimize disruptions, with robots adapting to material variations to enhance output and lower defect rates. In the pharmaceutical industry, AI predicts equipment degradation and optimises processes to uphold rigorous quality and compliance standards while reducing waste. Semiconductor facilities rely on AI to constantly fine-tune conditions in real time, ensuring maximum efficiency in highly sensitive operations.

For instance, impacts of predictive AI and self-optimising factories across multiple industries is commendable. As unplanned downtime costs the top 500 global companies around $1.4 trillion annually, making predictive AI essential for reducing losses. In automotive, GM cut downtime by 20%, Siemens lowered maintenance costs by 30%, Toyota reduced downtime by 40%, and Harley-Davidson boosted efficiency by 25% while halving maintenance delays. A European plant using Scops AI cut downtime by 40%, saving €1.5 million and avoiding over €100,000 in losses. Another manufacturer using Azure AI reduced downtime by 70%, cut maintenance costs by 45%, and achieved ROI within 9 months.

So, Predictive AI and self-optimising factories transform industries from reactive to anticipatory operations, allowing machines to predict problems and autonomously modify processes. This enhances productivity, quality, and robustness while enabling employees to concentrate on creativity instead of repetitive duties. As plants “anticipate ahead,” companies secure a competitive advantage by responding swiftly and minimizing waste. However, effective implementation demands fostering AI confidence, strengthening cybersecurity, and equipping the workforce for evolving, data-centric roles.